Hungary has always been a country shaped by its fields. From the Great Hungarian Plain to the hilly regions of Transdanubia, agriculture remains a central part of the economy and daily life. More than half of the country's land is used for farming, and crops like wheat, corn, sunflower, and barley continue to dominate the landscape. Yet in recent years, Hungarian agriculture has been going through a noticeable shift: farms are becoming more digital, more precise, and more focused on efficiency.

Hungarian growers face many of the same challenges seen across Europe - labor shortages, rising input costs, unpredictable weather patterns, and the pressure to produce more with fewer resources. At the same time, there is strong motivation to modernize. The government and various EU programs have been encouraging the adoption of smart farming tools, and young farmers in particular have shown interest in new technologies.

As a result, digital agriculture - once a niche topic - is becoming a real part of day-to-day farm management. Drones, sensors, automated tractors, and data-driven decisions are no longer futuristic concepts. They're tools farmers are beginning to rely on.

Agricultural drones are gaining traction in Hungary for three main reasons: they save time, reduce input waste, and help farmers manage larger areas with greater precision. In practice, their use falls into a few important categories:

1. Crop Spraying and Fertilizer Application

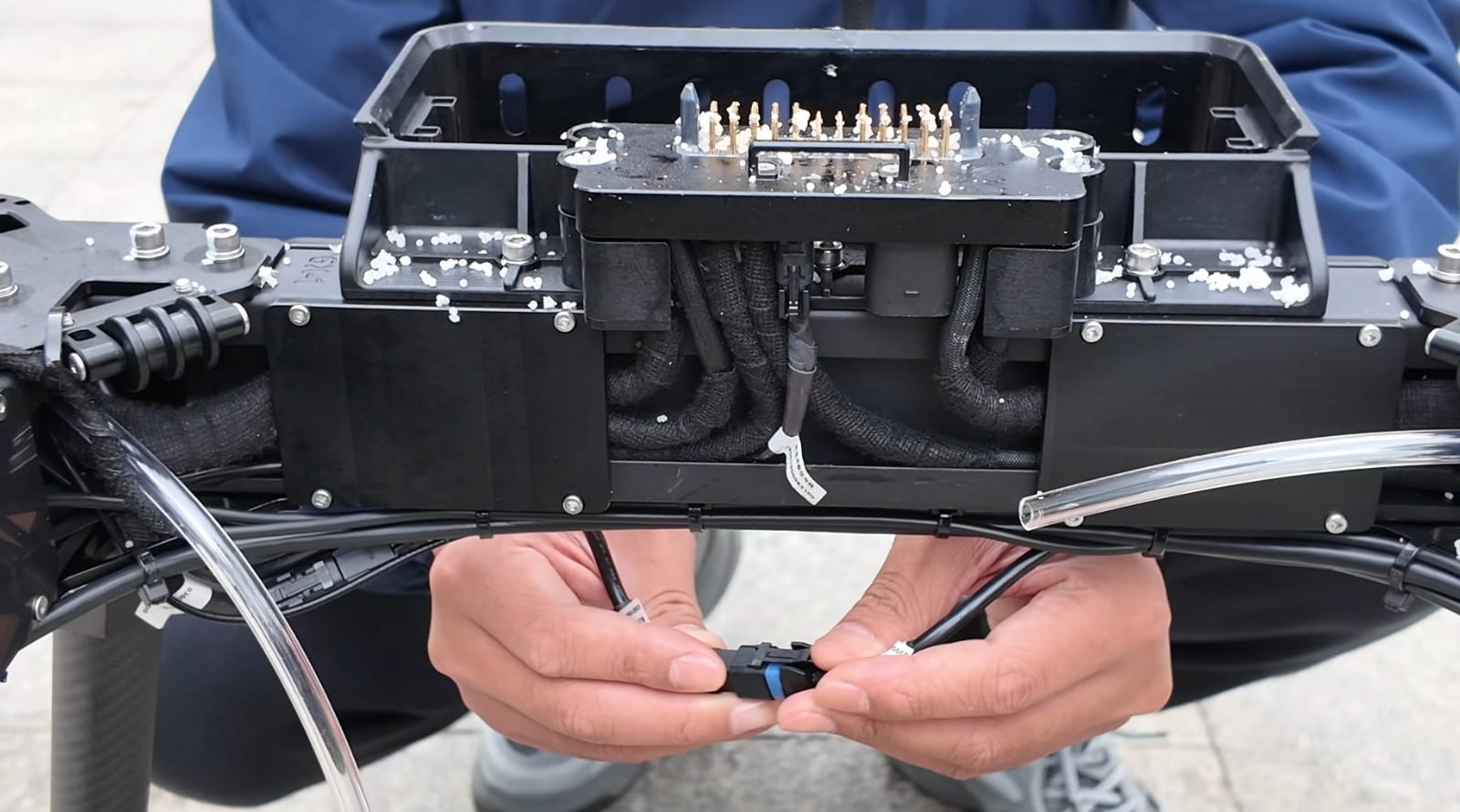

Aerial spraying drones are especially useful for areas that are difficult to reach with tractors - wet soil, uneven plots, or places where ground machinery causes crop damage. Models like the TopXGun FP700 agri drones offer high-capacity spraying and strong adaptability to local terrain, making them a good fit for Hungary's mixed crop structure.

2. Spot Treatment and Small-Plot Management

Hungary has many mid-size and small-scale farms, where precision matters more than sheer volume. In these cases, lighter and more flexible drones such as the TopXGun FP300E agri drones are well suited for targeted spraying, pest control, and applications that require careful control.

A few years ago, agricultural drones were still new to many Hungarian farmers. But the shift is speeding up because:

1. Regulations are becoming clearer, especially around drone operation and crop protection use.

2. Dealers and training centers are expanding, giving farmers easier access to support.

3. Farmers talk to each other, and many early adopters have shared strong results: lower chemical use, faster operations, and less labor dependency.

At TopXGun, we've seen a rising number of local partners and growers asking about practical, durable equipment - machines that can perform reliably through long seasons and varied field conditions. Both the FP700 and FP300E have been part of these conversations, especially in vegetable, orchard, and large-scale row crop applications.

Hungary's agricultural sector may not change overnight, but it's clearly moving toward a smarter, more efficient future. Drones won't replace traditional machinery, but they're becoming a valuable complement - taking over tasks that are time-consuming, labor-intensive, or require high precision.

As drone usage continues to grow, TopXGun will keep working with local partners to bring solutions that fit the needs of Hungarian growers - reliable tools that help them manage their fields with confidence.