In the age of e-commerce, most of the business including domestic and foreign enterprises is completed by email, which is really convenient for everyone.

However, as we know, there are many direct advantages to attend the exhibition and trade shows. Like Boosted Brand Awareness and Getting Noticed.

Make Central Location Sales and Secure Deals, Lead Generating New Opportunities, Trend spotting and Market Research.

Of course, it is a disadvantage to spend a lot of money and spend a lot of time in preparation.

For enterprises with a certain capital base, technological strength and sustainable development, they will still sell products and do business by attending exhibitions.

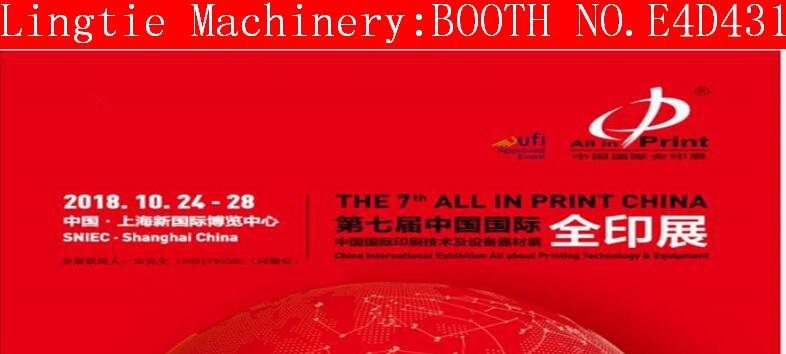

Lingtie Machinery is one of these enterprises.

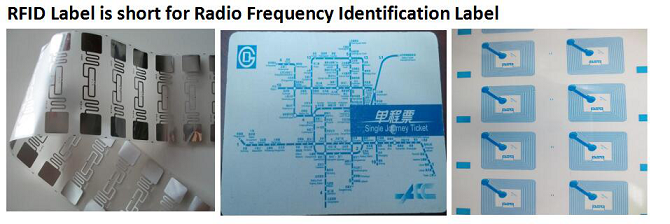

Lingtie Machinery in order to expand the roll to roll screen printing machine market, will attend the below Exhibition.

EXHIBITION: THE 7TH ALL IN PRINT CHINA( 2018.10.24-28), Lingtie Machinery BOOTH NO. : E4D431

EXHIBITION: CSGIA 2018 (2018.11.21-23), Lingtie Machinery BOOTH NO. : 2207

EXHIBITION: Printing South China 2019 (2019.3.4-6), Lingtie Machinery BOOTH NO.2328

EXHIBITION: Print China (2019.4.9-13), Lingtie Machinery BOOTH NO. 6-1100