Printed electronics including circuit board printing, RFID tags printing, RFID Antennas printing, which is a set of printing methods used to create electrical devices on various substrates. Printing typically uses common printing equipment suitable for defining patterns on material, such as screen printing, flexography, By electronic industry standards, these are low cost processes. Electrically functional electronic or optical inks are deposited on the substrate, creating active or passive devices, such as thin film transistors;

The most important benefit of screen printing is low-cost volume fabrication. The lower cost enables use in more applications. screen printing is appropriate for fabricating electrics and electronics due to its ability to produce patterned, thick layers from paste-like materials. Roll to Roll screen printing method is recommended to use for electronics printing. This method can produce conducting lines from inorganic materials, such as PC, PET, BOPP. Ink materials must be available in liquid form like solvent ink, water-based ink or plastisol and these inks must entirely dry due to they must function as conductors, semiconductors, dielectrics, insulators and passiveness layers.

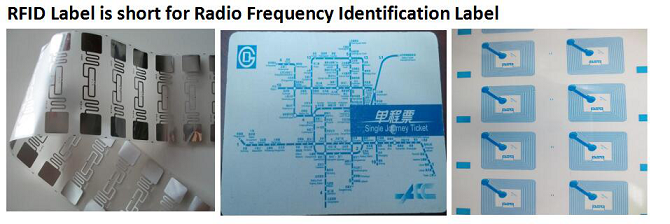

An example is RFID-systems including RFID tags, RFID Antenna, which enable contact-less identification in trade and transport, the picture for your checking.

We supply high accuracy roll to roll screen printing machine( be composed a feeding unit, a screen printing station and hot air dryer) for your Flexible Circuit Board printed, RFID tags, RFID Antenna printed, Membrane Switch printed or Nameplate Panel printed in monitoring, data storage, display and visual effects and toys industries.