guide rail, the printing plate and the working platform plays important role.

The adjustment of the parallelism between the three layers of the guide rail, the printing plate and the working platform: generally the guide rail or the platform is used as the reference for the adjustment. 1The platform and the guide rail should be parallel, and the squeegee plate moves along the guide rail. If the two are not parallel, the squeegee will not always touch the platform with a certain pressure, and even the gap will occur. This adjustment has been adjusted before the machine leaves the factory.

The screen printing plate and the platform should be parallel, otherwise the mesh distance (distance from the bottom surface of the screen printing plate to the printing surface) is inconsistent, causing the printing pressure and the screen printing plate to be inconsistent. Therefore, the flatness of the frame itself should be guaranteed.

Adjustment to the plate: refers to the adjustment of the printing precision between the screen printing plate and the printed object on the screen printing machine.

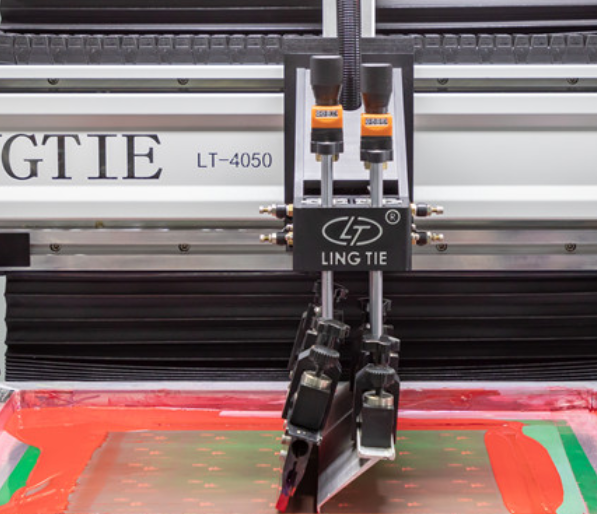

Squeegee adjustment: 1 Adjusting the parallelism of the screen by the squeegee, adjusting the left and right screw to adjust the height of the ink plate; the left and right sides of the middle shaft can be adjusted with the top wire to adjust the left and right top wires, and the height is adjusted to the right and left of the ink plate respectively. 2 The adjustment amount of the blade inclination angle is generally in the range of 65 to 85 , and can be selected as needed. 3 The adjustment of the printing pressure is actually the adjustment of the position of the squeegee. 4 The length of the squeegee can not be adjusted, generally supplied as a kit, each set has several different lengths to choose from. Stroke adjustment: including adjustment of stroke size and stroke position. Through the adjustment of the crank and the radius R of the swing rod, the stroke adjustment is realized, and the R increase stroke is increased, and the stroke length generally exceeds the pattern of 20 to 50 mm. Network (table) distance adjustment: the net (table) distance adjustment can be realized by reducing the screen printing plate or raising the platform, generally adopting the method of raising the platform. The screen plate four-corner net table spacing should be consistent, the error is 0.5mm. The distance between the nets is generally 2 to 5 mm, and the net is allowed to be smaller from the front and the rear only