Backed by decades of engineering experience, Jiaxin (Xiamen) Precise Metal Co., Ltd. specializes in precision metal stamping solutions tailored for demanding OEM and ODM applications.

In today’s highly competitive manufacturing environment, industries such as automotive, lighting, and household appliances require components that deliver consistency, reliability, and cost-efficiency at scale. Among all metal fabrication processes, custom metal stamping parts remains one of the most mature, stable, and economically advantageous technologies for producing high-volume precision metal parts.

This article provides an in-depth analysis of the advantages of custom metal stamping and why it is the preferred process across these major industries.

Understanding Custom Metal Stamping from an Engineering Perspective

Metal stamping is a process that transforms sheet metal into complex shapes using precision tooling and high-tonnage stamping presses. What differentiates high-quality stamping from general forming is:

1. Tooling Accuracy

High-precision dies (often 0.005–0.02mm tolerance control) determine part quality, cycle stability, and production cost.

2. Material-Forming Behavior

Engineers must evaluate:

Yield strength

Elongation

Springback behavior

Grain direction

Surface finish requirements

These parameters determine whether a part can be punched, drawn, or formed without cracking or deformation.

3. Progressive vs. Single-Process Stamping

Progressive dies integrate multiple forming operations into a single continuous process, ideal for high-volume automotive connectors, terminals, and brackets.

Single- or compound dies are suitable for large, thick, or structural components.

4. Tolerance & Dimensional Stability

Stamped parts often meet stricter tolerances than cast or welded parts due to the mechanical repeatability of stamping tools.

Why Custom Metal Stamping Is Essential for Automotive, Lighting & Appliance Industries

The engineering and economic benefits of stamping for major manufacturing sectors.

1. Automotive Industry, Meeting Safety and High-Reliability Standards

Automotive components face extreme mechanical stress, temperature fluctuations, and safety requirements. Custom stamping offers:

High Structural Integrity

Stamped components preserve material grain structure, resulting in stronger parts than cast or injection-molded alternatives.

Tight Tolerance Control for Assemblies

Automotive systems (chassis, braking, electronics) require parts that fit precisely with zero deviation.

Stamped parts can maintain tolerances as low as ±0.02 mm.

Excellent Reproducibility for High-Volume Production

Stamping provides:

Stable cycle time

Minimal dimensional drift

Long die lifespan

This is critical for Tier 1 and Tier 2 automotive suppliers.

Typical automotive stamping applications:

Sensor housings and terminals

Seat structure fittings

Brackets and reinforcement plates

ABS/EPS system connectors

Battery and EV hardware parts

Automotive-grade projects often require PPAP, control plans, and rigorous inspection — capabilities provided by experienced suppliers like Jiaxin.

2. Lighting Industry: High Precision and Thermal Management

Lighting systems rely heavily on stamped components for both structural and thermal functions.

Engineering benefits include:

High thermal conductivity for heat dissipation (especially aluminum reflectors or LED housings)

Lightweight structure for improved installation and energy efficiency

Surface uniformity required for optical performance

Excellent corrosion resistance for outdoor lighting fixtures

Common lighting components include:

Reflectors

Lamp bases and holders

Brackets for mounting systems

Aluminum housings for LED fixtures

Stamping ensures consistent geometry which is essential for light distribution and assembly alignment.

3. Household Appliances: Consistency, Safety, and Mass Production Efficiency

Appliance manufacturers require millions of consistent components annually. Custom metal stamping delivers:

Electrical Safety and Conductivity

Copper and brass stamped terminals provide reliable performance for motors, heating cores, switches, and control units.

Structural Stability for Long Lifespan

Stamped steel components offer rigidity for:

Washing machine frames

Refrigerator brackets

Oven panel supports

Precision for Mechanical Movement

Hinges, spring plates, and locking mechanisms rely on tight tolerances to function correctly over years of usage.

Typical appliance stamping parts:

Motor brackets

Mounting plates and hinges

Shield covers

Terminal connectors

Electrical housing components

Mass-production appliances rely heavily on stamping due to speed, consistency, and low per-unit cost.

Technical Advantages of Custom Metal Stamping

To better illustrate why stamping is favored over machining, casting, or welding, here are the core performance benefits:

1. Superior Dimensional Stability

Stamping dies are fixed tools — once optimized, every part produced maintains the same precision.

2. Material Utilization Rate Up to 80–95%

Progressive stamping minimizes scrap, significantly reducing cost, especially in copper and stainless steel.

3. High-Speed Production (Up to 800 Strokes/Minute)

Ideal for large-scale production of connectors, electrical contacts, and small structural parts.

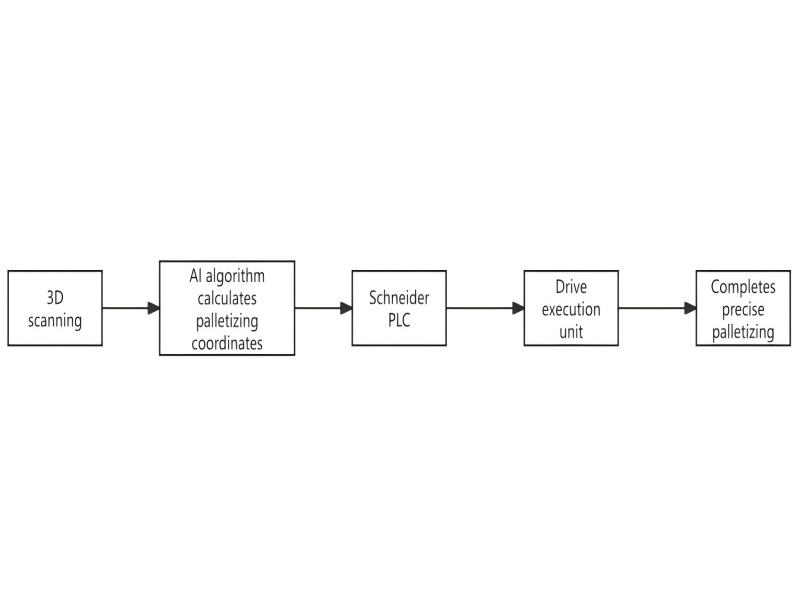

4. Compatibility With Automation

Stamped parts can be integrated directly into automated assembly lines, improving factory efficiency.

5. Excellent Surface Quality

Stamping produces clean edges and smooth surfaces suitable for polishing, plating, anodizing, and painting.

6. Long Tooling Life Cycle

Premium tool steels (SKD11, DC53, carbide) allow tools to produce hundreds of thousands to millions of parts without significant wear.

Why Work with Jiaxin (Xiamen) Precise Metal Co., Ltd.?

As a company with extensive experience in metal stamping engineering, Jiaxin provides capabilities that ensure project success from concept to production.

1. In-House Tooling Development

Faster lead time (typically 15–25 days for new tooling)

Better control of precision and cost

Full DFM (Design for Manufacturability) support for customers

2. Advanced Production Equipment

Including high-speed presses, precision progressive dies, and CNC secondary processing equipment.

3. Robust Quality Control System

Incoming inspection

First Article Inspection (FAI)

SPC and real-time dimensional monitoring

Full traceability of material batches

4. Multi-Industry Engineering Experience

Having served automotive, lighting, appliance, and industrial electronics sectors, Jiaxin understands varying industry standards and compliance requirements.

5. Flexible & Scalable Manufacturing

From initial prototyping to mass production, Jiaxin supports projects of all scales with consistent quality and on-time delivery.

With advanced engineering capability, comprehensive tooling development, strict quality control, and proven industry experience, Jiaxin (Xiamen) Precise Metal Co.,Ltd. is well-positioned to deliver reliable, cost-effective metal stamping solutions for global OEM and ODM customers. Welcome to visit us, Contact today.