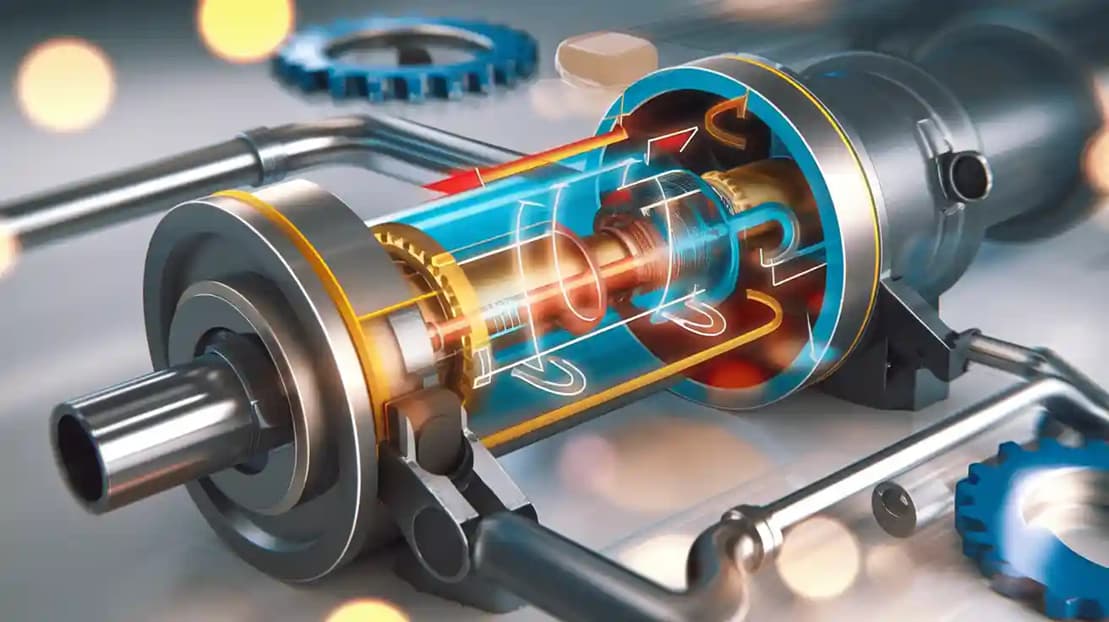

A hydraulic cylinder uses pressurized fluid to make force and movement in a straight line. You can find this device in many machines that need to press, pull, push, or lift heavy things. For example, you see small hydraulic cylinders working in forklifts, excavators, and trash compactors. These cylinders also help lift buildings, process food, and control farming equipment. They are very important in construction, waste management, mining, metal production, and farming.

Hydraulic Cylinder Overview

Definition

Some people call a hydraulic cylinder a hydraulic actuator. This device makes force and movement in a straight line by using pressurized fluid.

-

A hydraulic cylinder is a mechanical actuator. It gives force in one direction with a single stroke.

-

It turns hydraulic energy into mechanical movement. This makes the cylinder move in a straight line.

-

You can find hydraulic cylinders in machines like construction equipment, manufacturing tools, elevators, and civil engineering projects.

Hydraulic cylinders are special because they can make very strong forces.

-

These cylinders usually work at pressures from 1800 to 3000 psi. Some can go up to 5000 psi.

-

The force comes from multiplying the pressure by the area inside the cylinder.

-

Even small cylinders can lift or push heavy things. For example, a 3-inch bore cylinder at 2200 psi can move about 15,000 pounds. A 5-inch bore cylinder can move around 43,000 pounds.

Tip: Use hydraulic cylinders when you need strong and steady movement in a straight line.

Purpose

A stainless steel hydraulic cylinder changes the energy in hydraulic fluid into force. This force moves the piston inside the cylinder. The piston then moves the machine part that is attached to it. Hydraulic cylinders help you control heavy machines with smooth and exact motion. These devices are important in many machines because they give high force for less money. You will see them in factory automation. Their tough and simple designs make them easy to use. Hydraulic cylinders give you a low cost for each unit of force compared to electric actuators.

How Hydraulic Cylinders Work

Principle

A hydraulic cylinder changes fluid pressure into straight movement. When you put pressurized fluid in the cylinder, it pushes a piston. This force moves the piston forward. The piston then moves the machine part connected to it. The force depends on fluid pressure and piston size.

Pascal’s principle says pressure spreads everywhere in the fluid. The pressure is the same at both pistons. So, p1 equals p2. Since p2 equals F2 divided by A2, we get (\frac{F1}{A1}=\frac{F2}{A2}.) This shows how force and area work together in hydraulic systems. This works if pistons are level and there is little friction.

This principle lets hydraulic cylinders lift or push heavy things. You only need a small amount of fluid pressure. The movement stays smooth and easy to control.

Hydraulic cylinders have different pressure levels. Here is a table that shows common pressure ranges and uses:

|

Cylinder Type |

Pressure Range |

Applications |

|---|---|---|

|

Low-Pressure Cylinders |

Up to 1,000 PSI |

Light jobs like farm equipment |

|

Medium-Pressure Cylinders |

1,000 to 3,000 PSI |

Building machines and factory tools |

|

High-Pressure Cylinders |

Over 3,000 PSI |

Tough jobs like mining and steel work |

Operation Steps

You can split how a hydraulic cylinder works into easy steps:

-

Start the System: Turn on the hydraulic pump. The pump sends pressurized fluid into the cylinder.

-

Fluid Enters the Cylinder: Fluid goes into one side of the cylinder. This makes pressure push against the piston.

-

Piston Moves: Pressure pushes the piston forward. The piston rod comes out and moves the machine part.

-

Control the Direction: Valves change where the fluid goes. You can make the piston go out or come back in.

-

Retraction: To pull the piston back, fluid moves to the other side. Sometimes springs or gravity help bring the piston in.

-

Cycle Repeats: You can do these steps again and again for your job.

Here is a table that lists important parts and what they do when the piston goes back:

|

Component |

Function |

Importance in Retraction Process |

|---|---|---|

|

Valves |

Control fluid flow and direction. |

Make sure fluid goes to the right place for retraction. |

|

Release Mechanisms |

Help the piston return to start. |

Help pull the piston back, sometimes with gravity or weights. |

|

Fluid Pathways |

Let fluid move through the system. |

Make fluid flow smooth for good cycling. |

|

Return Springs |

Help pull the piston back. |

Lower the work for the system during retraction. |

|

Non-return Valves |

Let fluid go one way only. |

Stop fluid from going backward and keep movement steady. |

|

Pressure Relief Valves |

Keep pressure safe. |

Protect the system from too much pressure when pulling back. |

|

Accumulators |

Hold extra pressurized fluid. |

Give quick fluid for fast piston retraction. |

|

Control Levers/Switches |

Let you start and stop the piston. |

Give you control over pulling the piston back. |

A compact hydraulic cylinder uses these steps and parts to give strong and steady movement. You can trust this system for hard jobs like lifting or pushing heavy things.

Hydraulic Cylinder Components

Barrel

The barrel forms the main body of the hydraulic cylinder. You find this part holds the pressurized fluid and guides the piston as it moves. Manufacturers use strong materials for barrels to handle high pressure and wear. Most barrels use high-strength alloy steel or carbon steel. These materials give the barrel toughness and help it last longer. Some barrels have chrome plating or a honed surface to reduce friction and stop corrosion.

The barrel’s material matters for durability. Here is a table showing common choices:

|

Material |

Properties |

|---|---|

|

Low Alloy Steel |

Strong, flexible, tough, and resists fatigue. Handles extreme temperatures. |

|

Stainless Steel 301 |

High strength, resists corrosion, easy to weld, and very ductile. |

|

Nickel-Chromium Alloys |

Protects against oxidation and corrosion. Good at high temperatures. |

|

Carbon Steel |

Durable, affordable, and resists wear. Handles high pressure. |

|

Stainless Steel |

Contains chromium for corrosion resistance, great for marine use. |

Piston and Rod

The piston sits inside the barrel and moves when fluid pushes against it. The rod connects to the piston and sticks out of the cylinder. You use the rod to move or lift things. The piston creates force, and the rod carries this force to the outside.

-

The piston uses seals to stop fluid from leaking past it.

-

The rod must be strong and smooth to avoid bending and reduce wear.

|

Component |

Role |

Key Features |

|---|---|---|

|

Piston |

Moves inside the barrel to create force. |

Has seals to stop leaks and helps fluid flow smoothly. |

|

Rod |

Connects piston to outside load. |

Made from strong steel, smooth surface, size depends on job. |

Most rods use carbon steel, like C45 or 40Cr, for strength and cost savings. Stainless steel works well if you need corrosion resistance.

Seals

Seals keep the hydraulic fluid inside the cylinder and block dirt from getting in. You need good seals to keep pressure steady and avoid leaks. Seals must handle high pressure and temperature changes. You find different types of seals for different jobs:

-

Wiper Seals: Clean the rod as it moves, made from tough polyurethane.

-

Static Seals: Stay in one place, made from rubber or metal, resist high pressure.

-

Rotary Seals: Work with spinning parts, made from rubber or PTFE.

Seals protect the inside of the cylinder and help it last longer.

End Caps

End caps close off both ends of the cylinder. You rely on them to keep fluid from leaking out. End caps also guide the piston rod and hold everything in place. They help the cylinder stay strong under heavy loads.

-

End caps seal the cylinder and keep pressure inside.

-

They support the rod and piston, making sure they move straight.

-

End caps often have ports for fluid to enter or leave.

End caps add strength and help the hydraulic cylinder work safely and reliably.

Types of Hydraulic Cylinders

Single-Acting

Single-acting cylinders push or lift in one way. Hydraulic fluid moves the piston rod out. The rod goes back by a spring or the load’s weight. Only one port lets fluid in. This makes single-acting cylinders simple and easy to fix.

Single-acting cylinders are best when you do not need to pull with force.

Here is a table to compare single-acting cylinders with other types:

|

Feature |

Single-Acting Cylinder |

Other Types (e.g., Double-Acting) |

|---|---|---|

|

Direction of Force |

One direction only |

Both directions |

|

Inlet/Outlet Ports |

One port |

Two ports |

|

Retraction Mechanism |

Passive (weight or spring) |

Active (hydraulic force) |

You see single-acting cylinders in building, mining, making things, farming, and cars.

Double-Acting

Double-acting cylinders move in both ways. Hydraulic fluid pushes the piston rod out and pulls it back in. You can push and pull with the same force. These cylinders move faster and more exactly.

-

You control both the rod going out and coming in.

-

Double-acting cylinders work quicker than single-acting ones.

|

Advantage |

Description |

|---|---|

|

Manoeuvrability |

You get better control over movement. |

|

Efficiency |

These cylinders use less power and work better. |

|

Variety |

Many sizes for stroke and bore are available. |

|

ISO Compliance |

Meets world standards for quality. |

Double-acting cylinders are used in building, farming, making things, moving stuff, ships, and lifting materials.

Telescopic

Telescopic cylinders are also called multi-stage cylinders. They give a long stroke from a short starting size. These cylinders have tubes inside each other. Each tube, or stage, comes out one after the other. The biggest tube moves first, then the next, until all are out. When going back, the smallest tube goes in first.

Telescopic cylinders are great because they give a long stroke from a small starting size.

You find telescopic cylinders in dump trucks, cranes, drills, trash machines, and farm tools. They help lift or tilt heavy things when space is tight.

Tie-Rod and Welded

Tie-rod and welded cylinders are built in different ways. Tie-rod cylinders use long bolts called tie rods to hold them together. Welded cylinders have the barrel joined to the end caps by welding.

-

Tie-rod cylinders have bolts that run along the tube.

-

Welded cylinders have the barrel welded to both end caps.

|

Feature |

Tie-Rod Cylinders |

Welded Cylinders |

|---|---|---|

|

Construction |

Tie rods hold parts |

Barrel welded to end caps |

|

Pressure Capability |

Up to 3,000 PSI |

Up to 5,000 PSI or more |

|

Maintenance |

Easy to fix |

Small, strong design |

|

Durability |

Medium |

High |

|

Sealing |

Regular |

Better |

Use welded cylinders for high-pressure jobs. They last longer and work well in tough places. Tie-rod cylinders are easier to fix and fit many regular machines.

Hydraulic Cylinder Uses

Construction

Hydraulic cylinders are used on most construction sites. They help lift heavy things and move dirt. Big machines need hydraulic cylinders to work. Excavators move their arms because of hydraulic cylinders. Cranes use them to raise and lower their booms. Bulldozers, loaders, and dump trucks also use hydraulic cylinders. When you need to move a heavy part smoothly, you use a hydraulic cylinder. This technology helps you shape land and build strong buildings.

Manufacturing

Hydraulic cylinders make machines work faster and more exact in factories. Smart hydraulic cylinders can tell when they need fixing.

-

You get instant feedback about where the piston is. This helps you control machines better.

-

You can adjust movements to save material and make better products.

-

These cylinders use energy well and help stop sudden breakdowns.

-

Your machines last longer and work better.

-

Faster and more exact machines help you make more things with better quality and fewer stops.

Tip: Smart hydraulic cylinders can improve your factory by making every movement matter.

Agriculture

Farmers use hydraulic cylinders for many jobs on the farm. They help control water in irrigation and change sprinkler heights.

-

Plows and cultivators use hydraulic cylinders to set how deep and at what angle they work.

-

Seeders and planters use hydraulic cylinders to put seeds and fertilizer in the right spot.

-

You get better control of your tools, so you have better harvests and less waste.

Farmers trust hydraulic cylinders for hard work every day. You can rely on them for accurate and steady work in the field.

Hydraulic cylinders use pressurized fluid to make strong, straight movement. These devices have simple parts. The main parts are barrels, pistons, rods, seals, and end caps. There are different types you can pick. You can choose single-acting, double-acting, telescopic, tie-rod, or welded types. Hydraulic cylinders help in many areas. Their features fit many jobs:

|

Key Features |

Applications |

|---|---|

|

High Power Density |

Construction |

|

Precision Control |

Manufacturing |

|

Durability |

Agriculture |

|

Versatility |

Automotive |

|

Efficiency |

Aerospace |

Knowing about hydraulic cylinders helps you choose the right tool. If you want more information or need help, talk to an expert.