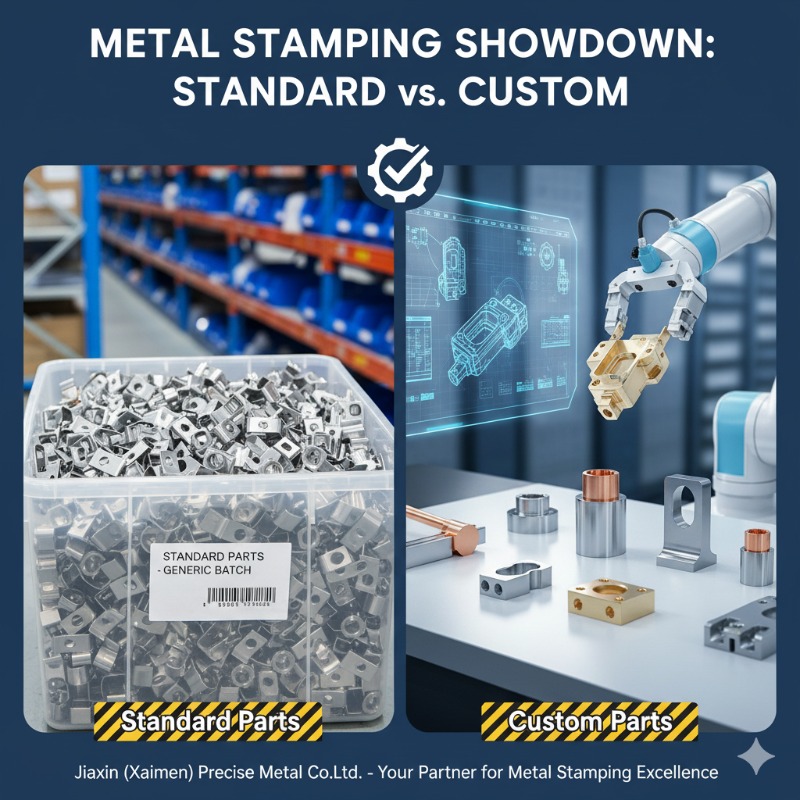

In the world of modern manufacturing, Metal Stamping Parts remain one of the most critical components across industries such as automotive, electronics, and construction. While standard stamped parts provide cost-efficiency and quick availability, more companies in 2025 are leaning toward customization. The debate often centers around which delivers better performance: standard components or Custom Metal Stamping Parts.

Standard vs. Custom: The Key Differences

Standard metal stamping parts are mass-produced with general specifications, making them accessible and budget-friendly. However, when applications demand higher precision, unique geometries, or specialized materials, Custom Metal Stamping Parts clearly take the lead. Customization ensures components fit seamlessly into specific designs, reduce waste, and often enhance performance in demanding environments.

Why Customization Matters in Modern Applications

In industries like electronics or automotive, custom features are no longer optional—they’re essential. A Custom Stamping Terminal, for example, allows for precise connectivity in electrical systems, ensuring safety, durability, and efficiency. By tailoring designs to exact requirements, manufacturers can improve product functionality, extend lifespan, and streamline assembly processes.

Choosing the Right Service Partner

The success of customization depends heavily on the expertise and reliability of the supplier. A trustworthy Custom Metal Stamping Service should combine advanced machinery, experienced engineering teams, and strict quality control to deliver consistent results. Beyond technical capabilities, responsive customer support and the ability to scale production are equally vital in today’s competitive landscape.

Why Choose Jiaxin (Xiamen) Precise Metal Co.,Ltd.?

When it comes to reliable Metal Stamping Parts, Jiaxin (Xiamen) Precise Metal Co.,Ltd. offers both standard and custom solutions that meet international standards. Their expertise in producing Custom Metal Stamping Parts, including Custom Stamping Terminals, makes them a preferred partner for businesses worldwide. What sets Jiaxin apart is not just product quality but also their dedication to service—offering flexible OEM/ODM options, competitive pricing, and fast turnaround times.

For companies seeking precision, durability, and responsive support in 2025, Jiaxin remains the go-to name for metal stamping excellence.