Colorfastness to perspiration measures a textile fabric's ability to maintain color stability without fading or bleeding when exposed to human sweat. It is a critical parameter in textile quality testing. Human sweat is a complex mixture containing water, salts (such as sodium chloride), lactic acid, urea, and other components. These elements may chemically react with dyes in the fabric or cause dye migration under the influence of sweat's moisture and temperature, thereby affecting the fabric's appearance and lifespan. This indicator directly impacts the wear experience and durability of garments, being particularly critical for intimate apparel (such as underwear and sportswear) and infant/toddler clothing.

1. Purpose of Sweat Resistance Testing

Sweat resistance testing methods evaluate a material's color durability when exposed to prolonged contact with human perspiration. This is critical for products in close contact with the body, such as apparel, footwear, and accessories. The test simulates the effects of sweat on materials over time, enabling manufacturers to assess colorfastness under real-world usage conditions.

2. Operating Procedure for Sweat Color Fastness Tester

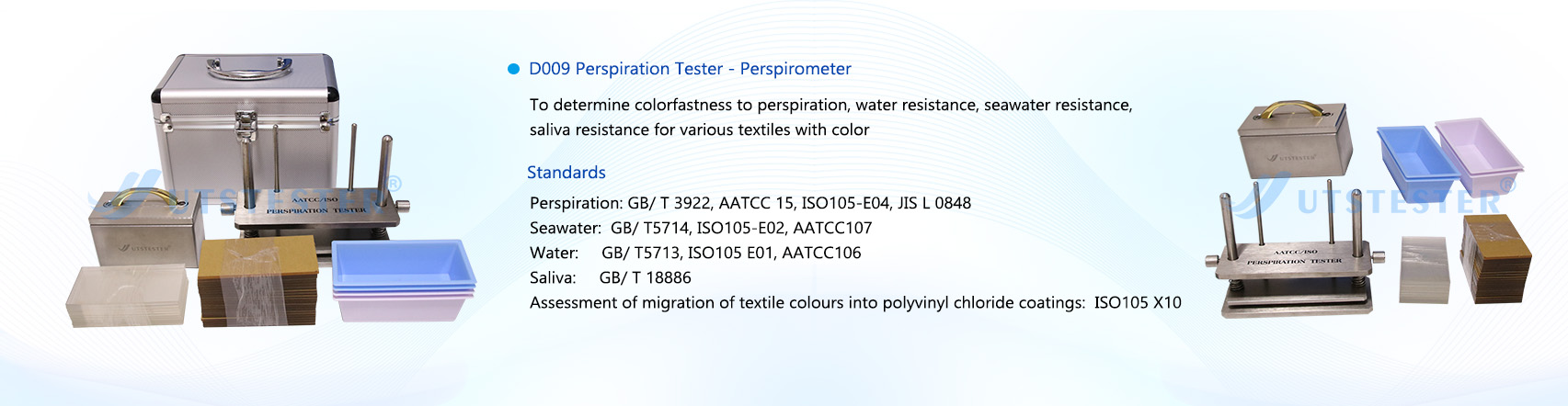

The GT-D09 Sweat Color Fastness Tester is suitable for assessing the sweat color fastness of various textile materials, dyed fabrics, and colored textiles. It evaluates resistance to sweat, water, seawater, saliva, chlorine bleach, and phenolsulfonated ethylamine.

Sweat fastness testing follows various international standards, such as ISO 105-E04, AATCC 15, and JIS L 0848. The test involves immersing textile or leather samples in a synthetic sweat solution containing specific concentrations of salts and acids to mimic human sweat composition.

The samples are then placed in an oven at a set temperature and humidity for a specified duration (typically 4-24 hours). After the sweat exposure period, samples are rinsed and dried, then evaluated for color change or staining using a gray scale or colorimeter. This test assesses color transfer from the material to other surfaces, as well as fading or discoloration of the material itself.

Sweat colorfastness test results are reported on a scale of 1-5 or 1-8, with higher numbers indicating greater resistance to sweat staining. This test is commonly used in the textile and leather industries to ensure products maintain their appearance and quality during use.

3. Significance of Sweat Testing in Textile Testing Methods

Sweat testing within textile testing methods holds significant importance in the textile and leather industries, as it provides manufacturers and consumers with valuable information regarding material quality and performance under real-world usage conditions. High levels of sweat colorfastness indicate that materials are less likely to fade or stain when exposed to perspiration, making them more durable and long-lasting.

Sweat fastness testing methods are standardized to ensure consistency and accuracy across different laboratories and testing facilities. This enables manufacturers to ensure their products meet industry standards and comply with regulations. Furthermore, this testing method can be used to identify potential quality issues in materials before incorporating them into finished goods, allowing manufacturers to address and correct any problems before they reach consumers.

4. Features of Sweat Fastness Testing Equipment

4.1. Steel frame and weight bags are constructed from 316L stainless steel, offering acid and alkali resistance with long-term corrosion resistance.

4.2. The sweat fastness tester provides ISO and AATCC acrylic separator plates.

4.3. The perspiration tester supplies ISO and AATCC standard pressing weights.

4.4. Perspiration testing requires the use of a high-precision drying oven.

5. Other Colorfastness Tests

Sweat resistance testing instruments represent only one of several methods used to evaluate the colorfastness of textiles and leather goods. Additional tests, such as wash fastness, lightfastness, and rub fastness, can be conducted to gain a more comprehensive understanding of a material's color durability.

Wash fastness testing involves subjecting materials to repeated washing cycles to assess resistance to fading or staining. Lightfastness testing exposes materials to artificial or natural light to evaluate resistance to fading. Rub fastness testing involves rubbing one material against another surface to assess resistance to color transfer.

6. Conclusion

In summary, the perspiration colorfastness test method is a crucial assessment technique used in the textile and leather industries to evaluate a material's resistance to fading or staining when exposed to human perspiration. This standardized test ensures consistency and accuracy, providing manufacturers and consumers with valuable information about a material's quality and performance under realistic conditions. Manufacturers can thereby ensure their products meet and comply with industry standards.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com