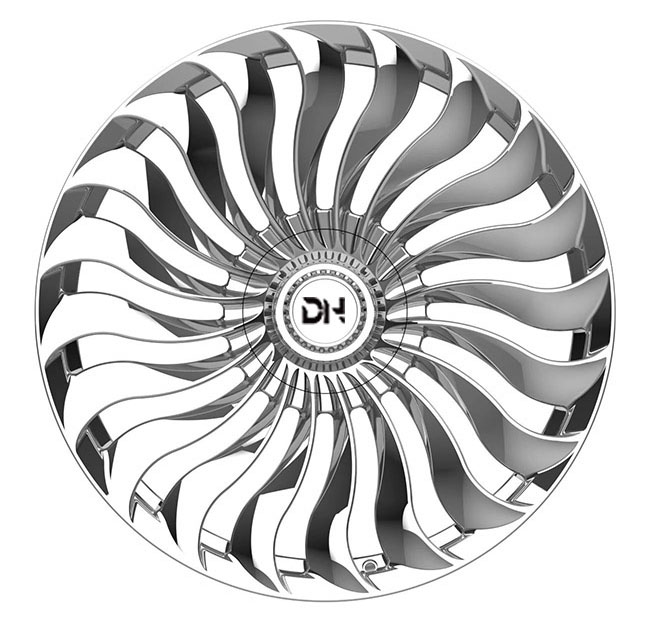

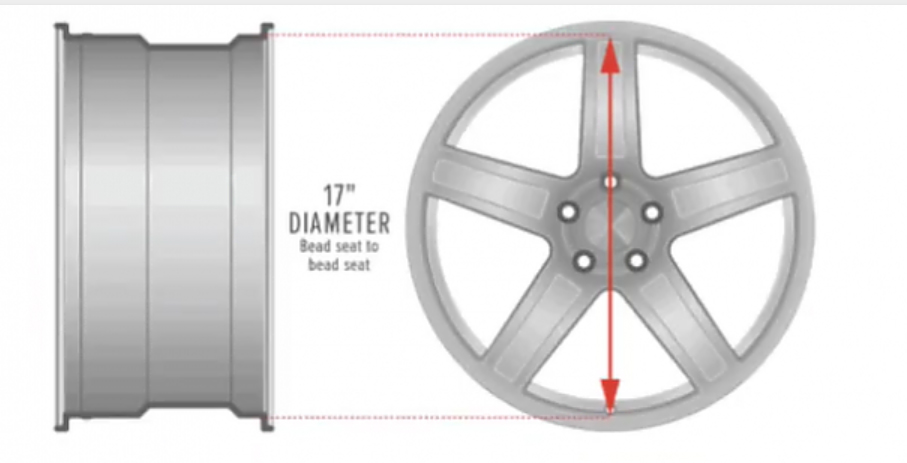

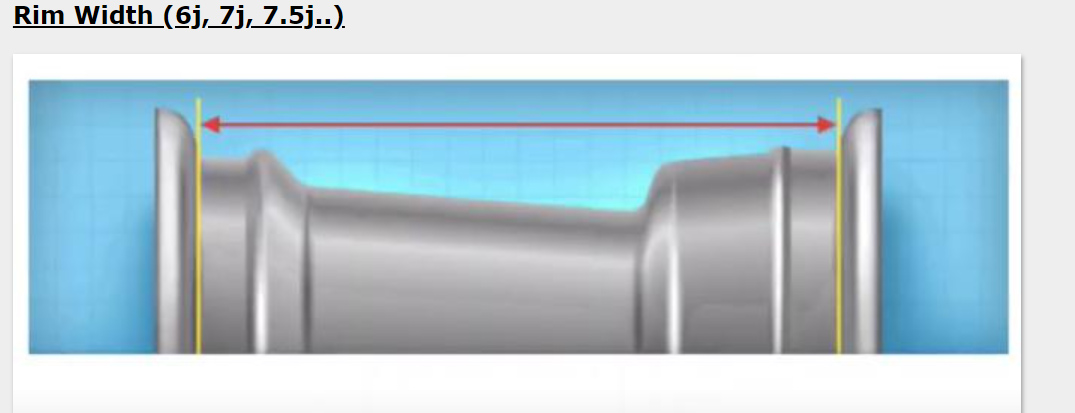

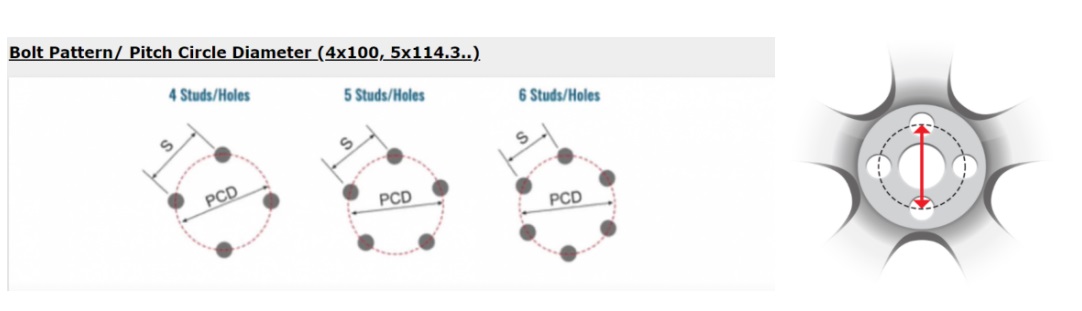

Happy to show this sleek silver wheel to you. Size:22x9.5, CB:78.1, PCD:6x139.7, ET:22. The wheel features a unique multi-spoke pattern, with each spoke expanding outward and tapering gradually, resembling a propeller design. This not only enhances the aesthetic appeal but also strengthens the wheel's durability and stability. At the center of the wheel, there is a circular DH brand logo, surrounded by raised edges, showcasing the brand's prestigious identity and adding depth to the wheel's design.

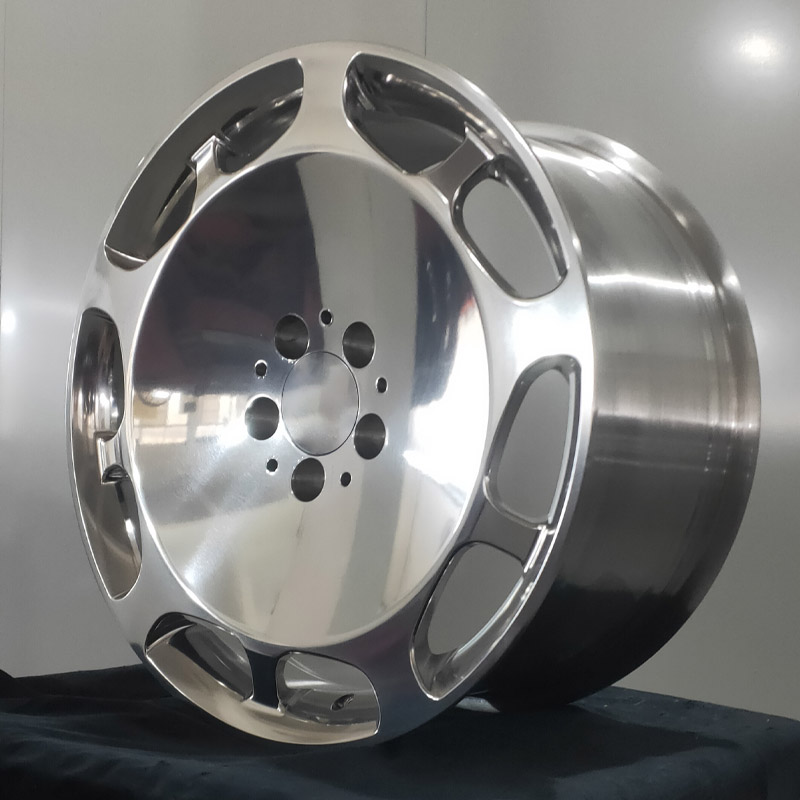

As a professional wheel manufacturer , DH always focuses on technological innovation and quality assurance. We utilize high-quality T6061-T6 aluminum alloy material and go through precise forging and polishing processes to create this wheel that combines exceptional performance with stylish appearance. Our wheels are not only lightweight and high-strength but can also be customized according to your needs, fulfilling your dual pursuit of vehicle performance and appearance.

The pure white background forms a striking contrast with the wheel, further highlighting its unique design and exquisite craftsmanship. Choose DH wheels and make your car a standout sight on the road!