A spectrophotometer is a scientific instrument that quantifies the amount of light absorbed or transmitted by a solution at any specific wavelength. Spectrophotometers are used for qualitative and quantitative analysis of chemical materials. Spectrophotometers are also commonly used in laboratories and research settings in fields such as chemistry, biology, physics, and materials science.

They are used for a range of activities, including enzyme activity, DNA/RNA quantification, color analysis, and quality control in manufacturing. Modern spectrophotometers can measure across multiple ranges of the electromagnetic spectrum (ultraviolet, visible, infrared), depending on the analysis being performed.

1.The Concept of Portable Spectrophotometers

A portable spectrophotometer is a small, handheld tool used to measure the absorption or reflectance of light to characterize the optical properties of samples outside the laboratory. It is also based on the same fundamental science as large benchtop spectrophotometers, primarily on the Beer-Lambert law.

1.1 Advantages and Limitations of Portable Spectrophotometers

Portable spectrophotometers offer advantages such as portability, on-site analysis capabilities, and user usability, making them suitable for fieldwork, quality assurance, and faster decision-making.

Advantages:

Portability—Small size and light weight allow for movement and use in factories and anywhere else you have quality issues, including in the field.

On-site Measurement—Measure in the field or online, eliminating the need to send samples to a laboratory.

Speed—Sometimes provides rapid results within seconds, facilitating quick decisions in high-risk situations such as forensic science or customs clearance.

Ease of Use: Typically designed for non-professional users and ease of use, intuitive even for non-technical users.

Non-destructive Testing: Enables non-contact measurements without damaging the sample when testing through packaging such as plastic and glass.

Limitations:

Accuracy and Sensitivity: The accuracy and sensitivity of the sensor may not match those of high-end stationary models.

Wavelength Range: The spectral range of many instruments is narrowed to enable accurate analysis.

Environment: Sensor performance can be affected by external forces such as temperature and light.

Sample Contamination: Sample contamination is more likely than in field applications.

Quantification: In some field applications, quantifying results can still be a challenging process.

2.The Concept of Benchtop Spectrophotometers

Benchtop spectrophotometers are stationary precision laboratory instruments used to measure the interaction between samples and light. Designed to deliver the most accurate measurements, they serve as exceptional tools for laboratory analysis, quality control, and color formulation across industries.

Spectrophotometers operate based on the Beer-Lambert Law, which states that the absorbance of light by certain substances is directly proportional to the concentration of the substance and the path length of light passing through the sample.

2.1 Advantages and Limitations of Benchtop Spectrophotometers

Benchtop spectrophotometers offer advantages such as precision, consistency, and broad flexibility for in-depth color and spectral analysis in stable laboratory environments, though they are less portable, more expensive, and require a controlled lab setting.

Advantages:

Precise Accuracy and Consistency: Benchtop versions deliver superior accuracy and stability. Consistent results are critical for working within tighter tolerances and achieving precise color matching.

Flexibility: Benchtop spectrophotometers can measure diverse samples, including solids, liquids, and powders. Most models offer multiple measurement modes (e.g., transmittance and reflectance) as standard.

Advanced Features: Many benchtop spectrophotometers now include useful functions such as adjustable apertures and additional viewing angles. Some quality control spectrophotometers can even analyze defects like haze, and some include backstops to minimize errors.

Data Analysis: Data from benchtop spectrophotometers can also be sent to a computer for analysis. If integrated into a Laboratory Information Management System (LIMS), this may include report generation or data analysis.

Limitations:

Non-portable—They are bulky and heavy. Due to their size, they remain plugged into a fixed location and cannot be used for field or on-site measurements.

Expensive—Benchtop spectrophotometers are typically significantly more costly than portable spectrophotometers, primarily because benchtop models are often more complex and/or feature more advanced optics or instrumentation.

Requires Controlled Environment—Desktop units must be set up and operated in a laboratory setting, which may not be feasible for all intended applications.

Operator Skill Requirements—Operating and interpreting results from a desktop spectrophotometer necessitates specialized knowledge and an understanding of the science behind spectrophotometric applications.

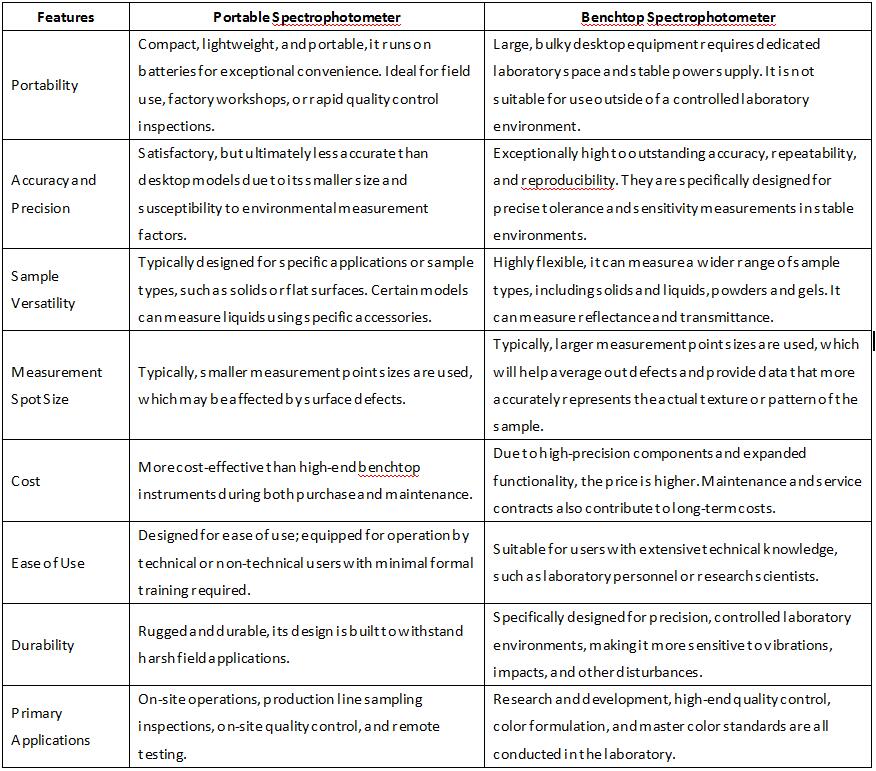

Differences Between Portable Spectrophotometers and Benchtop Spectrophotometers

Conclusion: Portable Spectrophotometers vs. Benchtop Spectrophotometers

Choosing between a portable spectrophotometer and a benchtop spectrophotometer depends on the tasks you will be performing. If you need to conduct on-site inspections, perform minute measurements, and/or frequently move the instrument, the portability and accessibility of a portable spectrophotometer may be your best option. If you require extremely high precision for research and measurement, perform spectral analysis, or operate in a laboratory setting, a benchtop spectrophotometer is the instrument better suited to meet your needs.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com