CNC milling is a precision manufacturing process that uses computer-controlled machines to remove material from a workpiece. Understanding the fundamentals of CNC Mill Basics involves knowledge of machine types, including vertical, horizontal, and 5-axis CNC milling machines, as well as the essential CNC milling tools and accessories required for different applications. The process includes step-by-step operations such as programming, setup, machining, and inspection, along with proper machine calibration and tool selection. Additionally, routine maintenance and adherence to operational standards are critical to ensure accuracy, efficiency, and longevity of both machines and tools. Together, these elements form a complete framework for performing effective CNC milling operations.

What is CNC Milling?

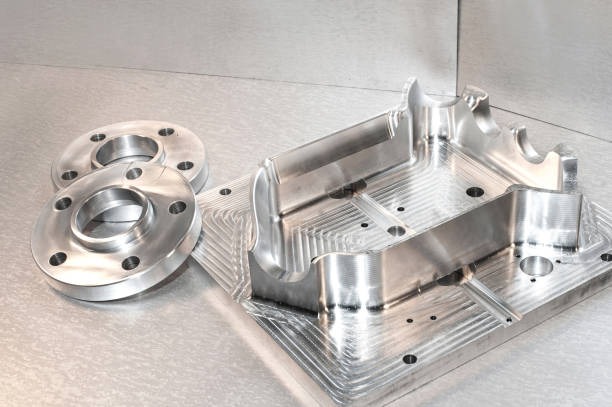

CNC milling is a subtractive manufacturing process in which a computer-controlled machine removes material from a workpiece to create a desired shape or surface. Unlike traditional manual milling, CNC milling relies on precise programming and automated tool movement, allowing for higher accuracy, repeatability, and efficiency. CNC milling machines, including vertical, horizontal, and 5-axis CNC milling machines, operate through a combination of cutting tools, spindles, and controlled axes to perform complex operations such as drilling, slotting, contouring, and surface finishing. Essential components include the machine base, spindle, worktable, control panel, and tool holders, all of which work together to execute precise machining tasks. The process is widely used in industries ranging from aerospace and automotive to mold-making and precision engineering, where consistent quality and tight tolerances are critical.

How CNC Mills Work?

CNC mills operate by following programmed instructions to move cutting tools along multiple axes, precisely removing material from a workpiece. The process begins with computer-aided design (CAD) to create a digital model of the part, which is then converted into a machine-readable code using computer-aided manufacturing (CAM) software. This code controls the movement of the spindle, the rotation speed of the cutting tool, and the positioning of the worktable, enabling the production of complex cuts and shapes with high precision.

Vertical, horizontal, and 5-axis CNC milling machines use different configurations to achieve specific machining goals. Vertical mills position the spindle perpendicular to the worktable, making them ideal for general-purpose milling and drilling, while horizontal mills use a spindle parallel to the workpiece for heavier cuts and slotting operations. 5-axis mills offer simultaneous multi-axis movement, enabling the efficient machining of intricate 3D surfaces and complex geometries.

Types of CNC Milling Machines

CNC milling machines come in different configurations, each optimized for specific machining tasks. The main types include:

Vertical CNC Milling Machines

Spindle oriented perpendicular to the worktable.

Ideal for drilling, boring, and general-purpose milling operations.

Easy tool changes and accessibility for small to medium-sized parts.

Horizontal CNC Milling Machines

Spindle positioned parallel to the workpiece.

Suitable for heavy cutting, slotting, and grooving operations.

Handles large and dense workpieces efficiently by distributing cutting forces.

5-Axis CNC Milling Machines

Provides simultaneous movement along five axes.

Enables machining of complex geometries, contoured surfaces, and intricate 3D shapes in a single setup.

Commonly used in aerospace, automotive, and mold-making industries for high precision and superior surface quality.

Specialized CNC Mills

Bed-type CNC mills: Large-scale production and stability for heavy workpieces.

Gantry CNC mills: Suitable for very large parts or workpieces requiring long travel distances.

Multi-spindle CNC mills: Efficient for high-volume production or multi-tool operations.

CNC Milling Tools and Accessories

|

Slotting, profiling, contouring |

Various shapes: square, ball nose, corner radius; different materials for specific applications |

Vertical, Horizontal, 5-Axis CNC Milling Machines |

|

|

Face Mills |

Surface cutting and finishing large flat areas |

High-efficiency material removal |

Vertical, Horizontal CNC Milling Machines |

|

Ball Nose Mills |

3D contouring, complex surface machining |

Ideal for molds, dies, and intricate shapes |

5-Axis CNC Milling Machines |

|

Drill Bits & Taps |

Drilling and threading operations |

Precision cutting, compatible with most setups |

Vertical, Horizontal CNC Milling Machines |

|

Tool Holders & Collets |

Secure cutting tools in the spindle |

Enhance precision, reduce vibration, extend tool life |

All CNC Milling Machines |

|

Fixtures & Workholding Accessories |

Positioning and securing workpieces |

Includes vises, clamps, and rotary tables; ensures repeatability |

All CNC Milling Machines |

|

Coolant Systems & Chip Management |

Maintain cutting temperatures, remove chips |

Improve surface finish, extend tool life |

All CNC Milling Machines |

CNC Milling Process Step by Step

The CNC milling process follows a series of precise steps to transform raw material into a finished component:

Design & Programming – A CAD (Computer-Aided Design) model of the part is created and converted into a CAM (Computer-Aided Manufacturing) program. This step defines tool paths, cutting parameters, and machining sequences.

Material Preparation – The selected raw material (such as aluminum, steel, or plastic) is cut to the required size and inspected for quality before machining.

Machine Setup – Cutting tools are installed, tool holders and collets are adjusted, and workholding fixtures are positioned to ensure stability and accuracy during milling.

Workpiece Mounting – The material is securely clamped on the machine table or fixture to minimize vibration and maintain repeatability.

Tool Path Simulation – A dry run or software simulation is performed to check for potential collisions, verify tool movements, and correct any programming errors.

Milling Operation – The CNC machine executes programmed cutting operations such as facing, slotting, drilling, contouring, or complex 3D milling. Operators monitor spindle speed, feed rate, and coolant flow for optimal results.

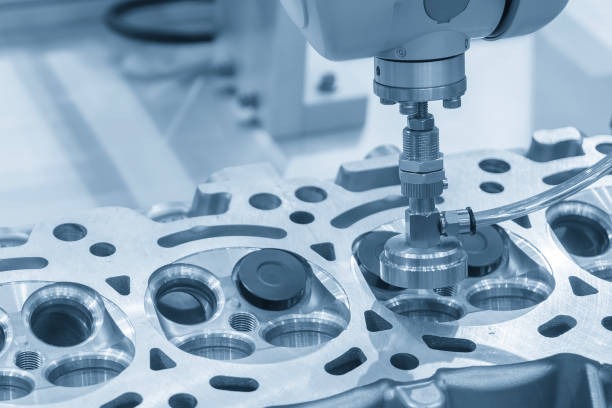

Inspection & Quality Control – Finished parts are measured using precision instruments to confirm dimensional accuracy and surface finish.

Finishing & Cleaning – Burrs are removed, surfaces are polished, and chips are cleared to prepare the part for assembly or delivery.

Setup & Operation Tips

Proper setup and operation are critical to achieving accuracy, efficiency, and long tool life in CNC milling. The following best practices help ensure stable machining performance:

Plan Tooling in Advance

Select the correct cutting tools, tool holders, and collets based on the material and machining requirements.

Use high-quality CNC milling tools to reduce vibration and maintain precision.

Verify Workholding Stability

Ensure fixtures, vises, or clamps securely hold the workpiece to prevent movement during machining.

Check for proper alignment to avoid dimensional errors and surface defects.

Calibrate the Machine

Set tool length, spindle speed, and feed rate according to the material and cutting operation.

Perform a test run or dry cut to confirm correct tool paths and eliminate potential collisions.

Use Coolant and Chip Management

Maintain consistent coolant flow to control cutting temperatures and extend tool life.

Remove chips frequently to prevent tool damage and improve surface finish.

Monitor Tool Wear

Regularly inspect end mills, face mills, and inserts for wear or damage.

Replace or resharpen tools as needed to maintain accuracy and avoid unexpected downtime.

Follow a Maintenance Schedule

Clean the machine bed, lubricate moving components, and check spindle alignment periodically.

Routine maintenance ensures consistent performance and prevents costly repairs.

By following these tips, operators can maximize the performance of CNC milling machines, improve machining quality, and reduce production costs.

Advantages of CNC Milling

CNC milling combines computer precision with advanced cutting technology to deliver exceptional results across a wide range of industries. Its greatest strength lies in accuracy and repeatability. Guided by CAD/CAM programming, CNC milling machines can consistently produce complex parts with tight tolerances, making them indispensable for aerospace components, automotive parts, and medical devices where even a small deviation can affect performance.

Beyond precision, CNC milling is remarkably versatile. Whether working with aluminum, steel, titanium, or engineering plastics, a single machine can perform multiple operations—such as slotting, drilling, contouring, and 3D surface milling—without the need for multiple setups. This flexibility allows manufacturers to handle both prototypes and mass production efficiently while reducing overall production time.

Efficiency is another key advantage. Automated tool changes, optimized spindle speeds, and multi-axis configurations enable continuous operation, which significantly increases throughput and lowers labor costs. At the same time, advanced tooling and stable cutting conditions result in superior surface finishes, often eliminating the need for secondary processing.

By combining precision, flexibility, and productivity, CNC milling offers manufacturers a cost-effective solution for creating high-quality parts at any scale. Whether for small-batch custom components or large-volume production runs, CNC milling machines remain one of the most reliable and competitive options for modern precision machining.

Conclusion

CNC milling stands as one of the most versatile and dependable methods for modern precision manufacturing. From the fundamental structure of CNC mills and their working principles to the variety of machine types, tools, and operational practices, every element of the process contributes to delivering accurate, efficient, and repeatable results. Whether creating prototypes, machining small custom components, or running large-scale production, CNC milling machines provide manufacturers with the flexibility to handle diverse materials and complex designs while maintaining exceptional quality.

For businesses seeking reliable machining solutions, investing in advanced CNC milling machines is more than just adopting technology—it is a strategy to enhance productivity, reduce costs, and stay competitive in demanding markets. By understanding CNC mill basics and applying best practices, manufacturers can unlock the full potential of this powerful machining process.