In today's era of increasing resource recycling and environmental awareness, glass color sorters, as highly efficient and intelligent sorting equipment, are being widely applied in the recycled glass recovery sector. They enhance sorting precision and efficiency, propelling the industry towards greater intelligence and sustainability.

What is a Glass Color Sorter?

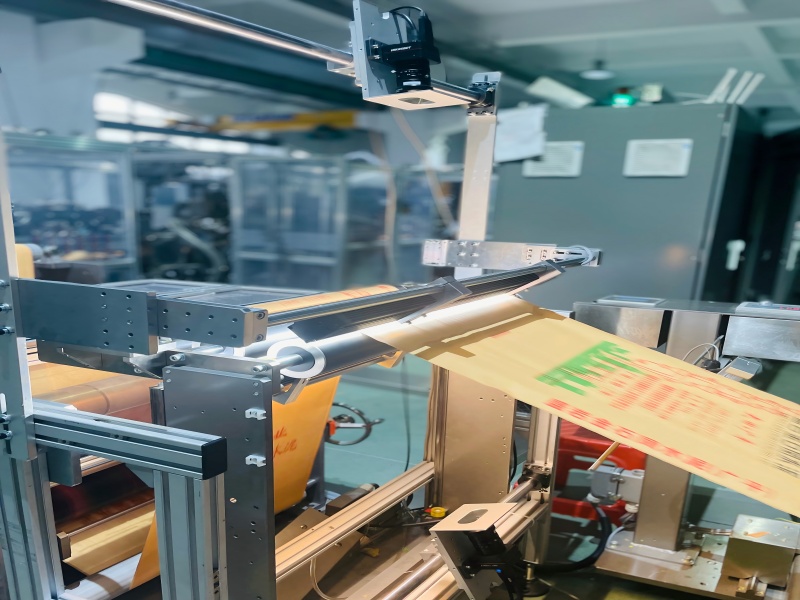

A glass color sorter is an automated sorting device that utilizes photoelectric recognition technology to identify the color, impurities, and shape of crushed glass. It employs high-speed cameras to capture image data, combined with AI image recognition algorithms and an ejection valve system. This enables the precise removal of glass of different colors or containing impurities, ensuring product purity.

Key Functions and Advantages of Grotech Glass Color Sorters

-

High-Precision Recognition: Utilizes advanced CCD cameras and AI algorithms to identify various colored glasses (transparent, green, brown, etc.) with an accuracy rate exceeding 99%.

-

Impurity Removal: Efficiently identifies and removes non-glass impurities like ceramics, metals, plastics, and paper, significantly improving recycled glass quality.

-

Strong Adaptability: Suitable for processing crushed glass particles ranging from 0.2mm to 50mm in size, meeting diverse process requirements.

-

Intelligent & Simple Operation: Features a touchscreen control panel and user-friendly interface. Supports one-touch intelligent adjustment and an automatic cleaning system for easy maintenance.

-

Energy Efficient & High Output: Scientifically designed valve layout, fast air jet response, low energy consumption. Processing capacity ranges from 2 to 10 tons per hour (depending on model).

Wide Range of Applications

Glass color sorters are extensively used in:

-

Waste glass recycling stations

-

Recycling resource processing plants

-

Beer bottle and beverage bottle crushing lines

-

Construction glass and automotive glass recovery systems

Through intelligent sorting, they effectively enhance the purity and economic value of recyclables, reduce labor costs, and lessen the burden on environmental processing.